Deep cycle batteries are essential components for various applications, from powering recreational vehicles (RVs) and boats to supporting renewable energy systems. However, over time, deep cycle batteries can degrade, leading to reduced performance and reliability.

In this article, we will explore how to effectively test a deep cycle battery to determine its condition and identify if it’s time for a replacement.

What is a Deep Cycle Battery?

A deep cycle battery is designed to be discharged and recharged multiple times and provide a steady amount of current over an extended period. It is ideal for applications that require a consistent energy output over an extended duration.

Common types of deep cycle batteries include:

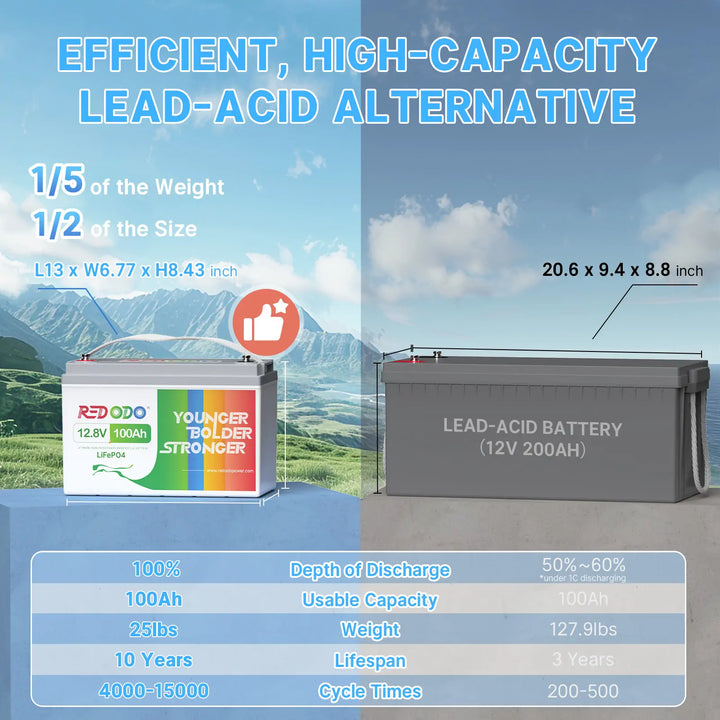

- Lead-Acid Batteries: These include flooded lead-acid and sealed lead-acid (AGM and gel) batteries, which are popular for their cost-effectiveness and reliability.

- Lithium-Ion Batteries: Known for their lightweight and high energy density, lithium batteries are becoming increasingly popular in applications requiring longer cycles and greater efficiency.

How to Tell If a Deep Cycle Battery is Bad?

Before you perform tests, it’s essential to recognize the symptoms of a failing deep cycle battery. Here are some common signs of a bad deep cycle battery:

- Decreased Runtime: If you notice that your devices are running out of power much quicker than before, your battery may be losing its capacity.

- Slow Charging: A battery that takes significantly longer to charge than it used to might be developing issues.

- Frequent Recharging: If you find yourself constantly recharging the battery, it may indicate capacity loss or damage.

- Corrosion: Visible corrosion around the terminals can impede electrical flow, affecting battery performance.

- Physical Damage: Cracks, bulging, or leaks indicate internal damage and can pose safety risks.

What May Causes Deep Cycle Batteries Go Bad?

Deep cycle batteries can fail for various reasons. Here are some common causes of deep cycle battery failure:

Over-Discharge

Deep cycle batteries are designed to be discharged to a certain level repeatedly. However, discharging them below their recommended depth of discharge (DoD) can lead to irreversible damage. For example, lead-acid batteries should not be discharged below 50% of their capacity, while lithium batteries can typically handle deeper discharges but still have limits.

Overcharging

Overcharging can cause excessive heat, leading to thermal runaway in lithium batteries or water loss in lead-acid batteries. This can damage internal components, reduce battery life, and potentially cause leaks or explosions. It's crucial to use a charger specifically designed for your deep cycle batteries and to follow the manufacturer's instructions carefully when charging them.

Undercharging and Corrosion

For lead-acid batteries, failing to fully charge can lead to sulfation, where lead sulfate crystals form on the plates, reducing capacity and efficiency. Additionally, corrosion at the terminals and connections can increase resistance, leading to poor performance and inefficient charging.

Temperature Extremes

High temperatures can accelerate chemical reactions within the battery, leading to faster degradation. Conversely, low temperatures can reduce the battery’s capacity and efficiency, making it harder to recharge. Ideally, batteries should be kept within a temperature range specified by the manufacturer.

Old Age

All batteries have a finite lifespan, generally measured in cycles (one complete discharge and recharge). As batteries age, their capacity diminishes, which can lead to shorter run times and increased self-discharge rates. For longer lifespan of deep cycle batteries, consider lithium batteries especially LiFePO4, which can last up to 10 years.

5 Ways on How to Test a Deep Cycle Battery

Testing a deep cycle battery involves several steps and methods. Here’s a comprehensive guide on how to perform these tests effectively.

Visual Inspection

Start with a thorough visual inspection of the battery.

- Check for Corrosion: Look for white, ashy deposits around the terminals. Clean any corrosion with a solution of baking soda and water. Ensure the battery terminals are secure and tight.

- Inspect for Physical Damage: Check for cracks or swelling. A swollen battery can indicate a failure or thermal runaway, which can be hazardous.

- Look for Leaks: Any signs of leaking electrolyte should be taken seriously, as this can indicate severe internal damage.

Use a Multimeter

A multimeter is an invaluable tool for measuring the voltage of your deep cycle battery.

Steps:

- Set the Multimeter: Turn the multimeter to the DC voltage setting. This is usually represented by a “V” with a straight line and dashed line underneath.

- Connect the Probes: Attach the red probe to the positive terminal and the black probe to the negative terminal of the battery.

- Read the Voltage: A fully charged deep cycle battery should read around 12.6 volts or higher. Here’s how to interpret your readings:

- 12.4 volts or lower: Indicates the battery is partially discharged.

- 12.0 volts or lower: Indicates a significantly discharged battery.

- 11.8 volts or lower: Likely means the battery is bad and may need replacing.

Load Test

Load testing is an effective way to assess the performance of a deep cycle battery. Here’s how to perform a load test:

Steps:

- Fully Charge the Battery: Before performing a load test, ensure that the battery is fully charged.

- Use a Battery Load Tester: This tool applies a specific load to the battery. The load should be equal to half of the battery’s rated amp-hour capacity.

- Monitor Voltage During Load: After applying the load for 15 seconds, check the voltage. If it drops below 9.6 volts for a 12V battery, the battery is likely bad.

Hydrometer Test (For Flooded Lead-Acid Batteries)

If you have a flooded lead-acid battery, a hydrometer can be used to assess the specific gravity of the electrolyte solution.

Steps:

- Remove Battery Caps: Carefully take off the caps from the battery cells.

- Insert the Hydrometer: Place the hydrometer into one of the battery cells and draw in some electrolyte.

- Read the Specific Gravity: A reading of 1.265 indicates a fully charged battery. Here’s how to interpret your results:

- 1.225 to 1.250: Partially charged.

- Below 1.200: Indicates a weak or bad cell.

Conduct a Capacity Test

A capacity test can provide a comprehensive evaluation of the battery’s health and performance.

Steps:

- Fully Charge the Battery: Start with a fully charged battery.

- Discharge at a Constant Load: Use a resistor or a light that draws a specific amount of current (around 25% of the battery’s rated capacity) and let it run until the battery reaches the cutoff voltage (typically around 10.5-11.5 volts for a 12V battery).

- Measure the Time: Note how long it takes for the battery to discharge. Compare this time against the battery’s rated capacity (in amp-hours). If the battery discharges much quicker than expected, it may be bad.

Capacity Test of Redodo Smart Bluetooth LiFePO4 Battery

When Should You Replace Your Deep Cycle Battery?

Knowing when to replace your deep cycle battery is essential for maintaining reliable power. If the battery consistently fails to hold a charge or shows significantly reduced runtime, it may be nearing the end of its lifespan. Most deep cycle batteries last between 3 to 10 years, so age is a crucial factor to consider.

If your battery is a few years old, or you find yourself frequently dealing with maintenance issues, such as corrosion or repeated recharging, it’s a sign that replacement might be necessary. Regular voltage checks and load tests can also help identify declining performance.

When it’s time to upgrade, consider the Redodo LiFePO4 Batteries for deep cycle. These batteries offer a longer lifespan with over 4,000 cycles in 100%DOD and enhanced safety features with advanced BMS. Lightweight and efficient, Redodo batteries are an excellent choice for reliable power in any application.

Tips to Maintain a Deep Cycle Battery Properly

Maintaining your deep cycle battery is essential for maximizing its lifespan and ensuring reliable performance. Here are key tips to follow:

- Regular Charging: Regularly charging your battery helps prevent deep discharge. Always recharge the battery after use, even if it seems only partially depleted. Consistent charging helps keep the battery in optimal condition.

- Avoid Extreme Temperatures: Store and operate your battery in a temperature-controlled environment whenever possible. Ideal temperatures are typically between 50°F and 95°F (10°C to 35°C). If using the battery in extreme conditions, consider thermal insulation or heating solutions.

- Use a Compatible Charger: Using a charger designed specifically for your battery type ensures proper charging. Make sure the charger is compatible with your battery type, either lead-acid or lithium technology. For 12V LiFePO4 lithium batteries, consider use the 12V LiFePO4 battery charger.

- Avoid Fully Discharge: Try to keep the battery above 50% state of charge whenever possible, in particular with a long-term storage. Implement a battery management system or a Bluetooth battery monitor if applicable, which can help monitor and control discharge levels effectively.

- Keep Terminals Clean: Regularly inspect the battery terminals for any signs of corrosion or buildup. Clean them using a mixture of baking soda and water, ensuring you disconnect the battery first to prevent any electrical issues.

Conclusion

Regular testing of your deep cycle battery to ensure its reliability and performance. By following the outlined methods and tests, you can effectively assess your battery's health and determine if it’s time for a replacement.

If you discover that your battery is bad, consider investing in high-quality alternatives like Redodo's lithium deep cycle batteries. These batteries offer superior performance, longevity, and efficiency, making them an excellent choice for your power needs.

Redodo

Redodo

Recent Post

6 Best Lightweight Trolling Motor Batteries in 2025

How Long Does a Trolling Motor Battery Last?

Convert RV from Lead-Acid to Lithium Battery: A Complete Guide

How Long Will a 200Ah Battery Run an Air Conditioner?

![⚡[$220 after Sign-Up] Redodo 12V 100Ah LiFePO4 Lithium Battery | Best Budget | For RV, Solar, Trolling Motor](http://www.redodopower.com/cdn/shop/files/Redodo_12v_100ah_lithium_battery_b9015ddd-64b5-4be2-8c88-392f0bb4ab30.jpg?v=1742973160)

![⚡[$220 after Sign-Up] Redodo 12V 100Ah Group 24 Deep Cycle LiFePO4 Lithium Battery | For Home, RV, Marine](http://www.redodopower.com/cdn/shop/files/Redodo_12V_100Ah_group_24_lithium_battery_6301965d-f6e8-467f-825f-3eec839b3e1f.jpg?v=1744105344)

![⚡[$220 after Sign-Up] Redodo 12V 100Ah Lithium Trolling Motor Battery With Low Temp Protection](http://www.redodopower.com/cdn/shop/files/Redodo12V100Ahlow-tempbattery.webp?v=1738462317)

![⚡[$239 after Sign-Up] Redodo 12V 100Ah Group 24 Bluetooth LiFePO4 Battery | Real-Time Battery Monitoring | For RV, Marine, Solar](http://www.redodopower.com/cdn/shop/files/Redodo_12V_100Ah_group_24_bluetooth_lithium_battery.jpg?v=1744253032)

![⚡[$220 after Sign-Up] Redodo 12V 100Ah Group 31 Bluetooth Lithium Battery | Real-Time Battery Monitoring | For RV, Marine, Solar](http://www.redodopower.com/cdn/shop/files/Redodo_12V_100ah_group31_bluetooth_lithium_battery.jpg?v=1745565708)

![⚡[$220 after Sign-Up] Redodo 12V 100Ah Mini Lithium LiFePO4 Battery | Smallest Battery | For RV, Trolling Motor, Solar](http://www.redodopower.com/cdn/shop/files/Redodo12V100AhMiniLiFePO4LithiumBattery.jpg?v=1739959054)

![⚡[$377 after Sign-Up] Redodo 12V 200Ah Lithium LiFePO4 Battery | 1280W Load Power | For RV, Solar, Off-Grid](http://www.redodopower.com/cdn/shop/files/Redodo12V200ahlithiumbattery.jpg?v=1735892910)